Wightlink, Portsmouth

Structural repairs and maintenance at Wightlink’s Portsmouth Station Terminal

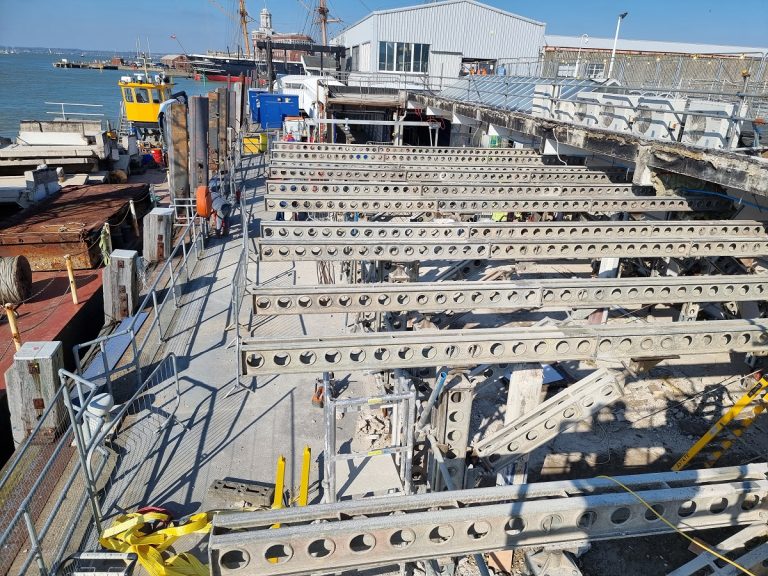

Temporary works

Mildren teams began by installing a temporary walkway across the roof of the existing terminal building. This facilitated safe pedestrian access to ferries during our works and included guarding ramps and gates along with temporary propping to support the reinforced concrete deck of the upper walkway and flat roof.

Demolition works

We isolated and re-routed existing remaining services. We then removed and set aside for re-use all glass screens, doors, powered sliding doors, the fire shutter, internal doors and internal demountable partitions.

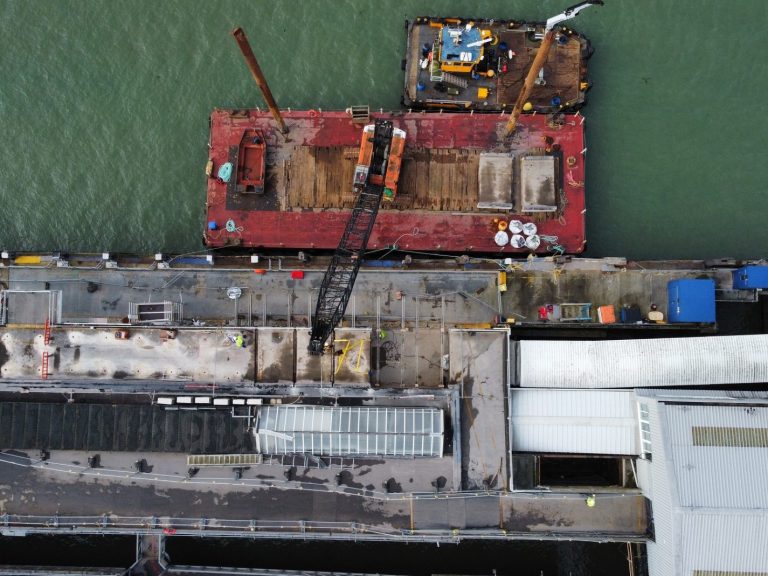

All remaining items were removed from site via barge; windows, blockwork, studwork, insulation, plasterboard, external doors, external cement board and ply cladding, rain water downpipes and asphalt roof covering.

Main works & structural repairs

The main works comprised removal of corroded steel support beams to the ferry terminal and their replacement. We also undertook works to steel columns supporting the upper part of the terminal.

- A crash deck was installed below the concrete floor whilst we cut the existing concrete floor into sections to allow it to be removed from the steel support beams, removed from site by barge

- Cut out and take off site steel beams supporting the concrete floor

- Repair existing column heads

- Supply and fit replacement main steel beams. Beam ends were measured and fabricated so bearings to pile caps did not require shims to support or level them

- Supply and fit replacement steel cross beams

Columns supporting the roof and concrete casings to the base of the existing columns were carefully cut, broken out and removed to a height of 1m. New replacement column bases were measured and secured in place. Whilst undertaking these repairs, the removal of the existing roof and installation of a new roof was instructed and undertaken as part of our main works.

Once steelwork repairs were complete, we installed pre-fabricated concrete floor planks and set them in place over the steelwork. The new roof structure was installed once the structural integrity of the new floor structure was complete with a single ply membrane roof system.

The external walls were of SFS construction, externally faced with Euroform Versaliner Sheathing and 8mm Trespa. The “set aside doors and windows” were reinstalled in the new openings, as were the internal doors, partitions, sliding doors and fire shutters.

Project challenges included:

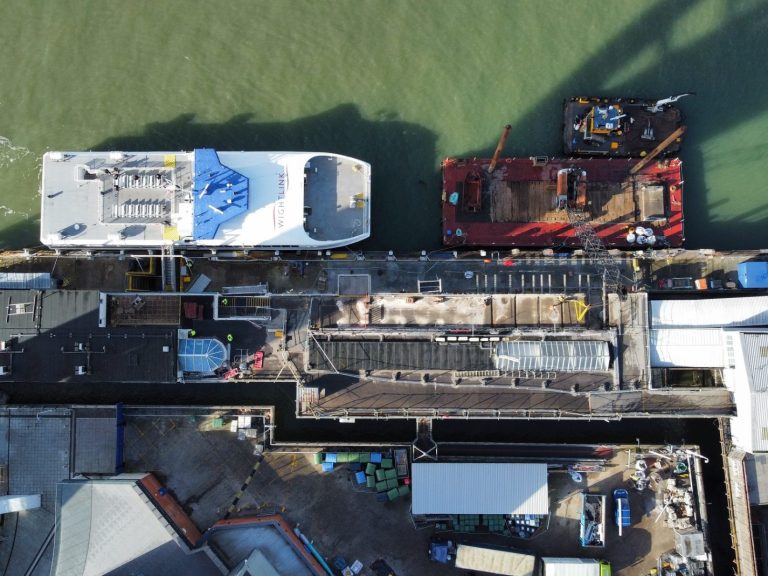

- The Wightlink terminal remaining in use during construction with working areas separated from the public and uninterrupted access to the ferries throughout the projects duration

- No landward access for vehicles, plant, and materials. All construction materials, equipment and spoil were delivered / removed via barge

- Working around a busy tidal passenger terminal, with spring tides rising to the level of the platform deck and restricted access at low tide

- Managing barge movements and access points to the ferry decking, including ‘out of operating hours’ as the harbour is used by other shipping including naval vessels – we had close coordination with the Wightlink team to manage this aspect

- Adjacent land use – Portsmouth Harbour Railway station has a passageway to the Wightlink terminal.

Contract duration

23 weeks

Contract type

Design and build

Wightlink, Portsmouth

Portsmouth PO1 2LA, UK